If code specifications or contract documents require notch toughness electrode selection should be limited to those that meet the specific application requirements.

Tungsten electrode tig welding filler rod chart pdf.

Tungsten electrode contamination is another common pitfall that can occur during tig welding.

Buy now 0 8 zirconiated white the 0 8 zirconiated electrodes are renowned for their extremely stable arc high resistance to contamination and resistance to tungsten splitting.

5 best electrodes are fleetweld 35 180 7 37 or 47.

The electrode is made up of materials which are similar to that of the metals chosen to be welded.

Larger diameters sustain higher amperages and last longer while smaller diameters allow for ease of starting the arc.

Tig welding produces no smoke and fumes unless the base metal contains contaminants or has a dirty surface tig welding doesn t produce slag and requires no flux because.

Filler rod 85 15 shield gas vertical 15 30 travel direction.

Indications that tungsten electrode contamination has occurred are.

Ideal for ac welding.

4 best electrodes are fleetweld 5p 5p 35 or 35ls.

An electrode or a welding rod is a wire which is made up of wire and is coated.

Tig welding tungsten electrode selection chart type ac.

They handle higher amp levels for magnesium.

A welder s choice of diameter ranges from 1 16 to 1 4.

Since the composition of the filler rod is the same as mig some of the same products are sold for tig welding identified as tig cut lengths.

To help you choose we ve provided some tips below.

These tungsten electrodes can be purchased in several quantities but typically come in 10pc packs.

One the weld puddle appears dirty.

They have varied diameters and come in seven or three inch lengths and which one.

Two the filler rod does not join or melt smoothly into the weld puddle.

Filler rods for tig are fed by a second hand as the first holds the tungsten torch.

By qualitytech july 13 2016.

Among all the other types of welding the stick electrode welding is considered.

Orbital tig pipe.

A tig welder needs a filler rod to provide the welding bead when joining two pieces of metal together tig welding produces no sparks or spatter because only the necessary amount of filler metal is added to the welding pool.

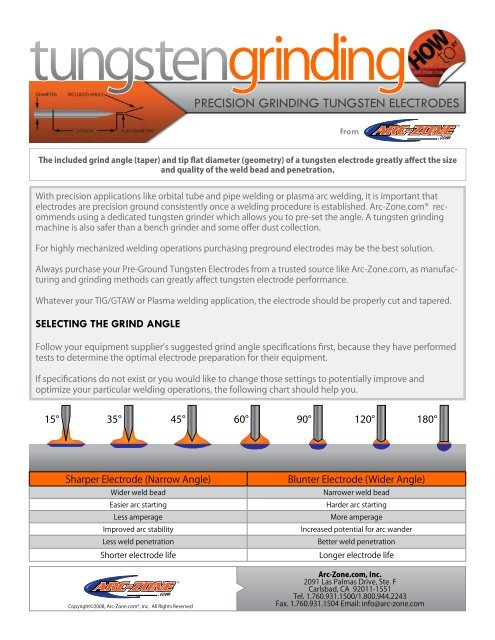

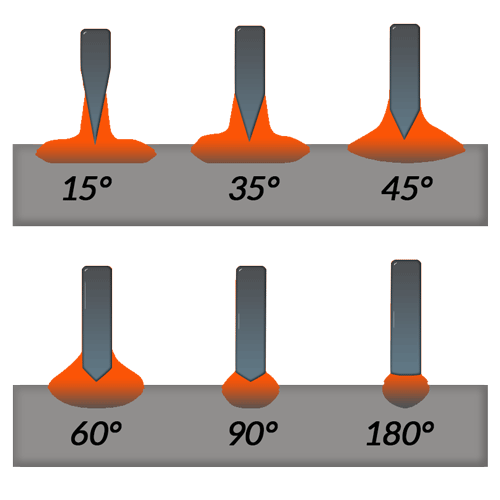

Applications for correctly ground cut and prepared tungsten welding electrodes for tig welding applications orbital tig tube welding to produce the high quality orbital fusion welds required of today s high tech industries tungsten electrode shape is an important variable that must be kept consistent.

Green electrodes are excellent for ac weld projects related to magnesium alloy or aluminum alloys.

Different types and sizes of tig welding tungsten electrodes in our product family.

These rods typically come in 3 foot lengths and are packed in 10 or 50 pound boxes or tubes.

Tungsten electrode tip shapes and current ranges correct torch and rod positioning take special note that the filler rod is in the shielding gas during the welding process.

Tungsten is hardy and has high heat resistance with the highest melting point of any metal 3 410 c 6 170 f.

Most orbital manufacturers require a precise tungsten length.

First select electrode based on the joint requirements.

Technically speaking the tungsten electrodes used in welding are not meant to serve as a filler rod.

Welding rod electrode selection chart.